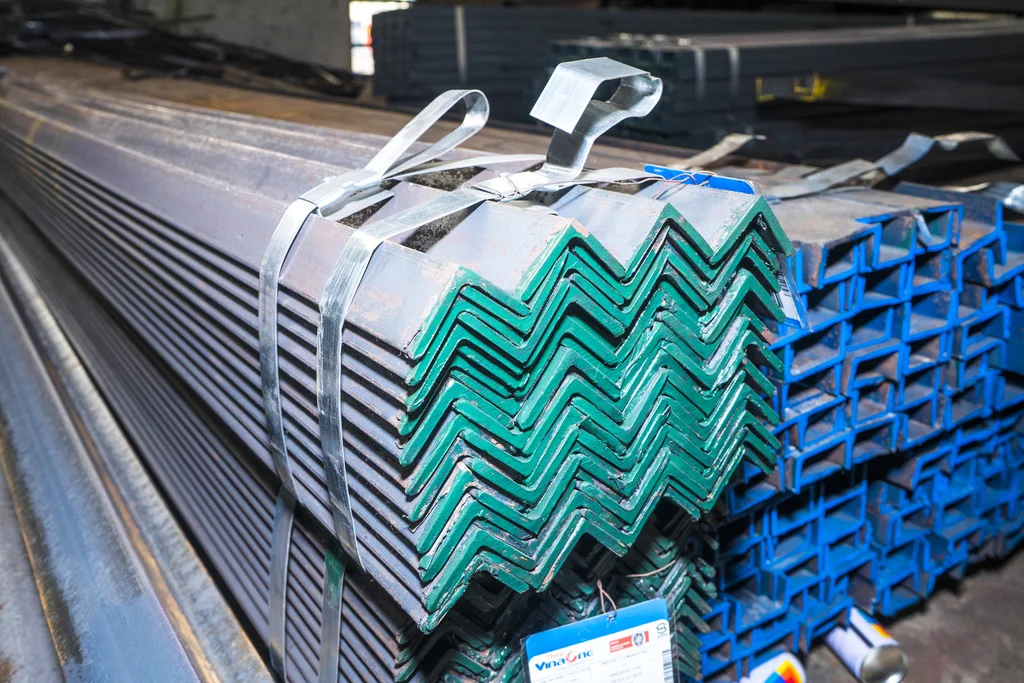

Mechanical processing using iron and steel materials accounts for the majority of the current processing market. Iron and steel is an indispensable material in daily life as well as in manufacturing and machine building industry. That was also the reason iron processing factories appeared everywhere.

Steel processing is the process of applying force to a material by different operations such as machines or by manual methods to create the required shape. With iron and steel materials, you can create many products at a cheaper cost than other materials on the market. Coming to Viet Duc Laser, you will receive the best iron and steel products at the most reasonable prices.

When a mechanical processing workshop opens, of course iron and steel are always the main source of raw materials. Therefore, the characteristic of mechanical processing workshops is processing iron and steel on demand.

However, you also need to understand that processing can not necessarily make products that meet the requirements for the size and aesthetics of the finished product. Because in a processing process, it needs to go through many different stages, so a small processing workshop will not be able to meet it.

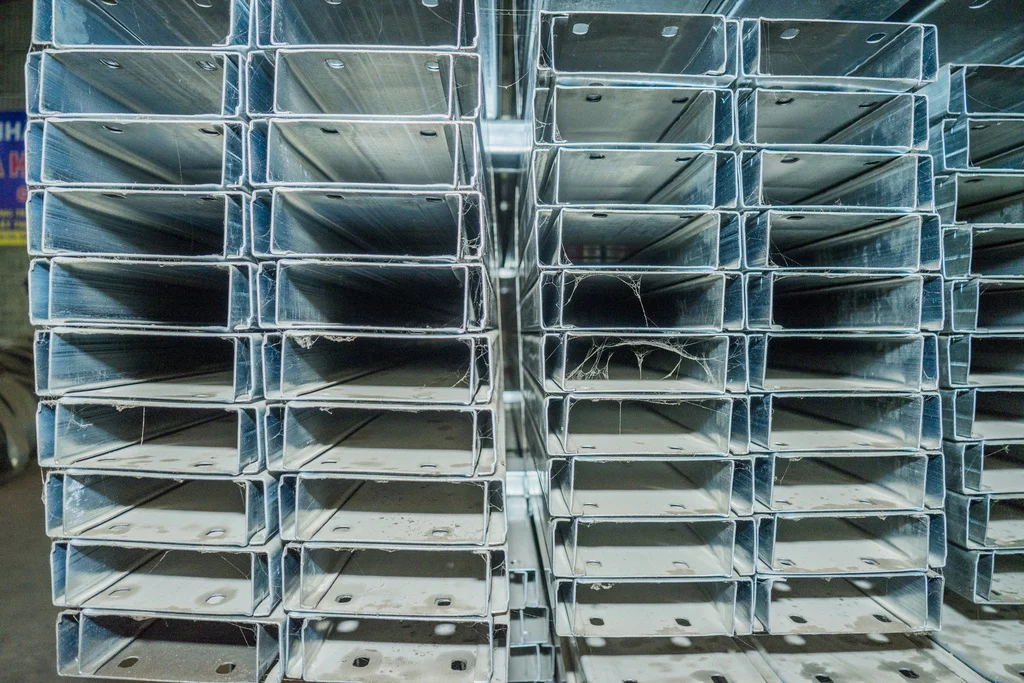

Not only with iron and steel materials, but any other materials will have to go through the same processing methods. It only has a difference in how to calibrate the machine and calculate the volume. Some common iron and steel processing methods are used most in iron processing workshops such as: stamping, turning, milling, welding, cutting, joining, bending.

Depending on the requirements of specific products, we will calculate and use other processing methods based on saving criteria for customers.

Steel processing is a form of processing to change the shape and size of iron and steel sheets according to customer requirements. Iron and steel is also a source of raw materials accounting for a high proportion in mechanical processing. In particular, it is also a material that is easy to process, so it is often chosen to be used a lot, except for specific purposes where people will choose to replace iron and steel with other materials such as stainless steel, cast iron, aluminum, equipment ...

The iron and steel processing factories in Dong Nai were sprung up very quickly due to the increasing demand for use. In today's life, steel processing has become one of the indispensable popular needs. However, to choose a reputable iron and steel processing factory is not easy.

And Hoang Dung's iron and steel processing workshop is the perfect choice for customers. Because we have many years of experience in the profession, the staff is enthusiastic about the profession. Not only that, we also have an investment in modern machinery and equipment, so we can ensure product quality and credibility for customers. We accept iron and steel processing on request, so all products made from iron and steel are processed by us.